OPTOELECTRONICS LABS

Cameras, displays, LEDs and optical sensors are a few examples of optoelectronics devices, key product interaction components. In our Optoelectronic Labs, we have all the necessary tools to design, develop, integrate, and optimize these components for your final product.

Our labs offer key equipment needed during product development projects such as design, component selection, benchmarking, tuning, verification, and validation. Our Optics lab facilities are a part of our legacy from Ericsson and Sony Mobile and have been a central part of our offer since the foundation of Sigma Connectivity in 2013. Since then, upgrades have been made to keep us competitive in mobile phone development and increase our flexibility to develop products with optical components across a broad range of consumer, medical and industrial applications. Some recent examples are mobile phones, wearables, stand-alone streaming and conference devices, IR sensors for people detection, endoscopes, 3D cameras, and ToF ranging sensors, to name a few.

CAMERA LABS AND IMAGING SYSTEM DEVELOPMENT

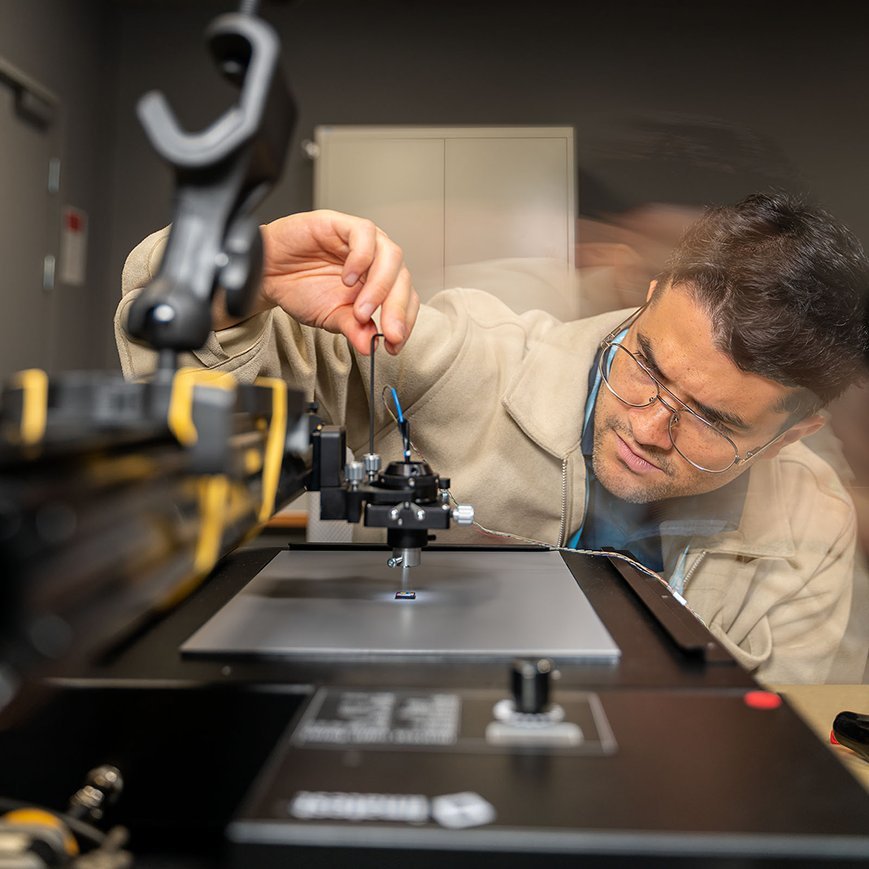

An imaging system is comprised of different components such as image sensors, lenses, actuator systems for focus or stabilization, illumination sources, image signal processors (ISP) and post-processing algorithms. The imaging system development is usually a two-part process; selecting and integrating the system hardware components followed by the ISP image tuning. The Sigma Connectivity camera labs are set up so we can support you through parts of both stages or the full imaging system development. Read more here.

-

We have the tools and expertise to evaluate them as individual components or as a complete imaging system through both objective and subjective methods. Subjective evaluation is performed using still-life and repeatable setups to match real-life scenes and/or specific scenes. Objective evaluation is based on image analysis of reflective and transmissive test targets.

Typical image quality factors measured in our lab:

Sharpness | Distortion | Field of View (FoV) | Color reproduction | White balance (WB) | Veiling glare | Ghost and Flare | Blemish | Flicker | Dynamic Range (DR) | SNR and noise measurements | Contrast (OECF) | Aberrations |IR-sensitivity/response

Other essential parts of a camera lab are known light sources with different properties. We can reproduce various illumination conditions and environments through our specialized equipment.

Large-scale lab for object distances up to 10 m and up to 160° FoV

Precision close-up lab for macro photography such as endoscopic imaging

Light booth to reproduce CIE standard luminants (Horizon, A, D50, D65, D75, Fluorescent)

lightSTUDIO with dimmable LED-based light sources (iQ-LED V2) to reproduce any type of visual light source

Controllable light panels and boxes for transmissive targets

Computer-controlled linear motion stage to characterize motion blur

Standardized reflective and transmissive camera test targets for image quality measurements

Dynamic Range station with lightbox up to 100,000 lux and >150 dB dynamic range targets

Calibrated reference monitors for visual assessment of images.

Dedicated rooms can be set up according to customer requirements

Computer vision lab for 3D sensing applications

Subjective room: home-like environments, conferencing etc

-

We can support you and your project at the very earliest stage by scoping the needs and choosing the most suitable sensor/lens/platform combination for your product. Performing evaluation and benchmarking on camera sensor development kits and lens samples are recurring tasks for our team as well as guiding our customers through the prototype phase up to mass production along with the camera module supplier. During the development, our engineers and labs can support you with verification, common issue investigations, and to some extent, validation (highly case-dependent). Typically, several or all the image quality factors mentioned above are evaluated at this stage to settle the image system hardware baseline before proceeding to image tuning.

-

Camera tuning involves tuning and testing the different blocks within an image signal processor (ISP) in the lab to optimize image quality. Some examples are color reproduction, contrast, tone mapping, noise reduction, sharpening, and texture enhancement algorithms, as well as 3A tuning, which includes auto exposure control (AEC), auto white balance (AWB), and autofocus (AF). Besides this, we can also test and verify specific features like HDR, image stabilization (EIS/OIS) and distortion correction. Our tuning experience covers multiple chipset platforms (Qualcomm, MediaTek, NXP, custom ISP or FPGAs) and image sensors (Omnivision, Sony, Onsemi, Samsung), using either supplier tools and/or development kits in our labs.

DISPLAYS AND TOUCH SENSORS

Sigma Connectivity has extensive experience in product development, system integration, and testing of most display technologies (LCD, OLED, e-paper etc.). Contrast ratio, readability, dynamic backlight control, and anti-reflective coatings are all important display features that can be optimized and measured in our labs. We have a dedicated display measurement station with a calibrated spectrometer where one can characterize key performance factors:

Luminance | Contrast ratio vs viewing angle | White point | Color gamut and Color reproduction | Transmission and Reflectivity | Uniformity | Response time |Polarization orientation | Temperature effect | Frame rate

We also have extensive experience in product development, system integration, and capacitive and optical touch panel module testing. Using our touch robot station and other equipment available, we can characterize and ensure the performance of a touch solution:

Accuracy | Response time | Linearity | Precision | Jitter | Noise | Response time | Latency | Charger noise | Gestures | Temperature effects

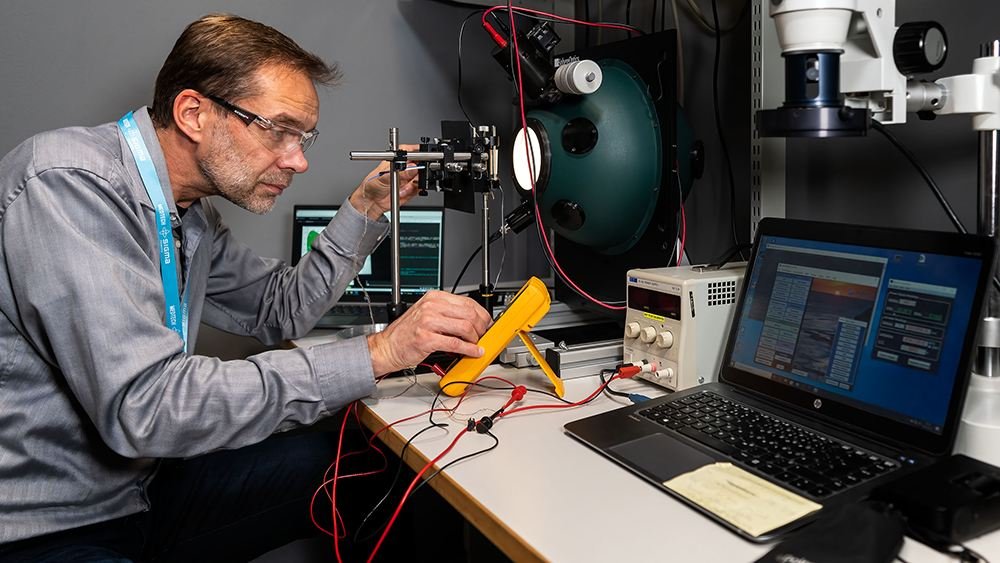

OPTICAL SENSORS

The optoelectronics team also has long experience with all types of optical sensors. Examples include light- and color sensors, IR proximity sensors, ToF ranging sensors, biometric sensors, and IR sensors for all wavelengths, including PIR/Thermopile/Bolometer/TMOS for human body temperature sensing. Optical sensing elements are also included in a large variety of other types of sensors, and for each type of sensor, the requirements for laboratory measurements may differ. But the optoelectronics team is well prepared to handle all of the labs and set up a suitable test environment.

SIMULATIONS

We can work in any part of the process, from simulations with tools like Zemax and LightTools, and MATLAB through design, integration, and verification of components or products. Typical examples are light guide design, lens optimization, and camera simulations.

LIGHT SOURCE & GENERAL OPTICAL MEASUREMENTS

We have the equipment to measure the spectral and intensity (photometric and radiometric) response of any light source within the visual spectrum, as well as infrared and ultraviolet solutions. Examples of typical components we measure in our labs are LEDs, flash and torch light solutions, light bulbs, indicator lights, light guides and infrared illuminators. Besides this, we can also characterize materials such as windows, cover glasses and plastics to understand the effect material selection will have on the optical system of the final product. Typical measurements:

Electrical characterization | Flash uniformity | Dynamic | Luminance and Illuminance | Intensity vs viewing angle| Flux measurements | Spectral power distribution | Colorimetric analysis (CIE, CCT, CRI) | Logging of dynamic characteristics | Transmission and Reflectivity

-

We have specialized equipment and tools often used to build a test setup station to fit a specific application or test during product development.

Integrating spheres suitable for small sources up to larger lighting solutions

Calibrated spectroradiometers, photometric and radiometric measurementsCalibrated light and chroma meters

Specialized filters, diffusers, lenses, and mirrors

Accuracy Translation/rotation stages

Opto-mechanics and optical table

Controlled climate chambers for temperature or aging tests

Reference system cameras and benchmark devices

-

We have specialized equipment and tools often used to build a test setup station to fit a specific application or test during product development.

Imatest Master for IQ evaluation

iQ-LED for LED light source control

MATLAB & Image Processing Toolbox

Qualcomm ISP tool Chromatix, and corresponding tools from MediaTek and NXP

Iset – Image System Engineering Tool

Internal tools for image sensor simulation and camera evaluation

Contact our team

Mattias Eriksson

Engineering Manager, Optoelectronics & Audio Design

![Measuring - Imaging Lab [Social Media].jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/534b3a85-b366-4a63-a1f1-5b9315198c4b/Measuring+-+Imaging+Lab+%5BSocial+Media%5D.jpg)

![Light board - Imaging Lab [Social Media].jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/afe81e84-feec-4cd6-956a-6534981f80c9/Light+board+-+Imaging+Lab+%5BSocial+Media%5D.jpg)

![Focusing - Imaging Lab [Social Media].jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/155612e6-0762-4799-a47a-e40c80743c7d/Focusing+-+Imaging+Lab+%5BSocial+Media%5D.jpg)

![HDR - Imaging Lab [Social Media].jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/1c6f743b-9319-4329-af25-770a005fbc55/HDR+-+Imaging+Lab+%5BSocial+Media%5D.jpg)

![Controlled Light III - Imaging Lab [Social Media]_OPTO.jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/fccb03e2-f574-45e1-822b-a6ee190681e6/Controlled+Light+III+-+Imaging+Lab+%5BSocial+Media%5D_OPTO.jpg)

![Controlled Light II - Imaging Lab [Social Media].jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/b6251990-3cc0-4c37-a90b-687f38b88d9b/Controlled+Light+II+-+Imaging+Lab+%5BSocial+Media%5D.jpg)